August 6th, 2021

posted

by Lou Herbers on 8/6/2021

in

Weekly Newsletter

August 6th, 2021

Fertility Update

We are in the home stretch of producing this year’s crop and our thoughts turn to preparing for harvest and the fertility requirements of next year’s crop and beyond. We can take a few cues from the field right now to give some additional direction for next year.

We have become increasingly aware of the importance of sulfur (S) in our fertility programs for corn. The picture below was taken northeast of Exira early in the week. The area with yellowing is showing classic sulfur deficiency because of an application error. The corn in adjacent areas received 100# of AMS (21-0-0-24S) last fall and looks good. It is easy to confuse nitrogen deficiency with sulfur deficiency this late in the season without walking the field and looking at individual plants. Incidentally, this field had 100# of CalSul (21% Ca, 17% S) applied in the fall of 2019 ahead of the soybean crop in 2020. Obviously, there is very little carryover S from that application done almost two years ago.

Sulfur deficiency has become more apparent in soybeans over the past 10-14 days. This is occurring primarily in fields that had no S application ahead of this year’s soybean crop. Keep in mind that S in the sulfate form is mobile in the soil and therefore transient. For that reason, I think it is mostly a waste of time to soil sample for sulfur. Sulfur deficiency will be most pronounced on lower organic matter soils. The worst areas I see are often on eroded sidehills although it can appear anywhere. The picture below shows sulfur deficiency symptomology in a soybean field.

Historically, many farmers have fertilized ahead of the corn crop with a two-year blend for both the corn and subsequent soybean crop if in rotation. The soybeans get whatever “leftover” fertilizer is there after the corn. We need to start thinking about applying sulfur to both our corn and soybean crops the way we think about applying nitrogen to our corn crop. For some of you, this is old news as we started fertilizing this way 5 years ago or more. One of my favorite programs is to apply 100# of CalSul flat rate and variable rate apply potash ahead of soybeans. When Calsul solubilizes in the soil water it splits into its components of SO4 and Calcium, both nutrients required by the soybean plant. The effect on soil pH is neutral. All other forms of sulfur that we commonly use have an acidifying effect on the soil. This does not make them bad; it just makes Calsul an especially good choice ahead of soybeans. AMS and ATS (liquid) are also good choices if cost effective. Most manures are a good source of sulfur and useable if they can be applied uniformly.

For the most part the nitrogen applications done either last fall or this spring look good. It appears that there is very little N deficiency unless there was an application error. Many years we can see yellowing in some of our glacial till sidehills due to nitrogen loss that had occurred during wet periods. This is largely absent this year and I expect some very good yields from these lower CSR soils this year.

Phosphorus and potassium deficiencies are harder to spot late season and both nutrients are part of a longer-term soil fertility plan that includes regular soil testing. If you are part of our normal testing program every 4 years, Mike will be sending you information on farms that are due to be sampled. If you haven’t had any soil testing done recently and would like to get on a regular program, please contact Mike.

Fertilizer Supply and Pricing

What a difference 18 months can make! I guess you can say the party is over. Historically, higher grain prices have resulted in higher fertilizer prices. This time is no exception; however, the magnitude of change is amplified as we are coming off of 15-year lows and now are sitting in the upper 20% of the historical price range for most products. In all cases, world demand has been strong. Sometimes it doesn’t make sense to us why prices are what they are until we step back and look at it from a global perspective. I will address each nutrient individually.

Nitrogen

Summer fill values on all nitrogen products are about double what they were a year ago. I don’t look for this market to soften any before winter and may even strengthen further by next spring. Supply is snug on all forms of N due to strong usage this spring and a “system” that was drained empty this spring. Additionally, many plants skipped their annual shutdowns for maintenance a year ago because of limited employees on site during Covid. Those shutdowns are now taking place and may be extended because of a backlog of maintenance items.

Sulfur

A year ago, I wrote how ATS (liquid) had dropped in price to be equivalent to our dry forms of sulfur. We are awaiting summer fill values, but indications are that they will be at least double last summer’s prices. AMS (dry) was also a great value a year ago. I mentioned to many of you that I was able to buy it at the lowest level that I could remember. That product will be nearly double in price this coming year. The lone standout with a “modest” price increase is Calcium Sulfate (CalSul). This product is manufactured by Calcium Products in Ft Dodge. They have announced a $10/ton increase. There were product shortages this spring and I expect that to continue into fall, especially with the relatively good value of this compared to other forms of sulfur.

Potash

Potash pricing had been increasing steadily since last fall. We were offered limited tons in April for summer fill and shortly after that all bids were pulled from the market. On Thursday, Nutrien announced a sharp price increase with Q4 pricing that was exactly $200/ton higher than April. Retail prices may vary widely depending on how much product was secured earlier at lower price levels. Several things are driving potash higher along with strong worldwide demand. On the supply side, Mosaic closed a couple shafts at their Esterhazy, Saskatchewan mine 9 months early due to flooding and unsafe conditions. This reduced supply by several million tons. Political turmoil in the country of Belarus is causing uncertainty about whether that country’s production will continue to be exported or be restricted due to sanctions. Belarus accounts for 15% of the world’s potash production capacity. I think most retailers have a decent position on potash so I doubt you will see the full $200/ton increase show up at the retail level, but it is an indication of the future price direction.

Phosphorus

Phosphate pricing has more than doubled compared to 18 months ago and there is little relief in sight. The combination of strong worldwide demand and limited imports into this country from Morocco and Russia due to the countervailing duty imposed on those imports is truly creating a physical shortage of product. Mosaic filed and won this lawsuit and is now actually asking for the duties to be higher than what was awarded. This market needs to figure out different avenues of bringing product into this country before we can see lower prices.

New Product Update

We have purchased a new to the market phosphate product called Croplex that was recently introduced by Eurochem. This is a high quality, low dust formulation that will fit our needs well. We have shipped the product and it is available in our warehouse. Some of the highlights of this product are as follows:

- Analysis is 12-40-0-10S-1Zn+ 1/3 B

- 8-9 Lbs higher crush strength than competitive NPS homogeneous products

- 5# sulfate S and 5# liquid elemental S. Liquid is smaller particle size and more easily weathered and broken down into a plant useable form vs the dry elemental others use.

- 1/3 # of Boron Trioxide. This form is more slowly mineralized vs sodium borate and more sustainable for late season boron supply

- Lower heavy metals and impurities in the phosphate rock supply.

I had the opportunity to run a truckload of this through a dual placement bar last fall with great results. With the increase in sulfur pricing this product has become very competitively priced compared to other options available. You will hear me talking more about this product going forward.

Facilities and Equipment Update

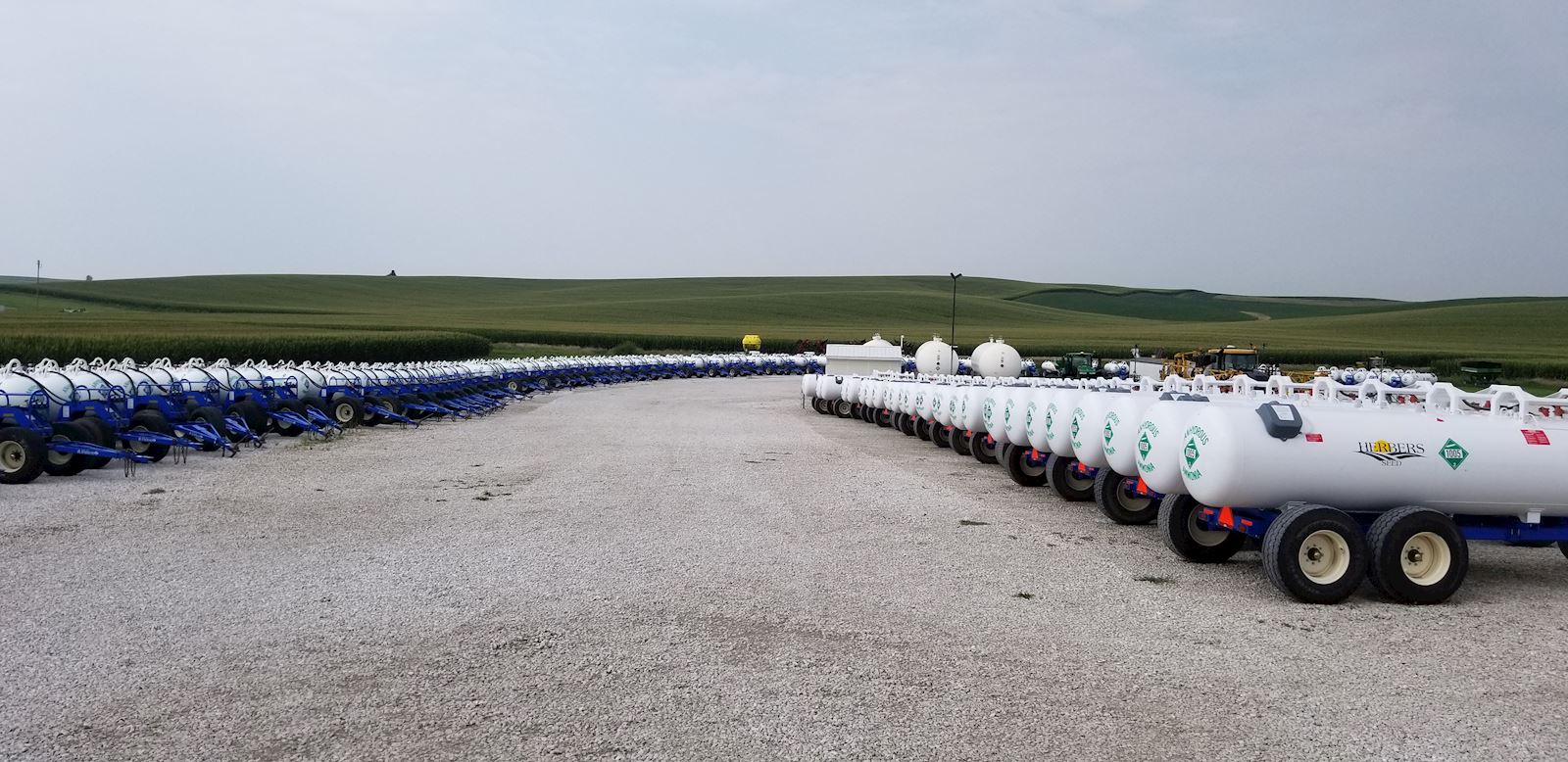

Herbers Seed continues to invest in updating equipment and facilities. I would challenge you to find better maintained equipment and facilities anywhere in our industry. Collin and his crew have completed summer maintenance on our 78 sets of ammonia tanks. They are all filled and ready to go. The ammonia plant pumps have been rebuilt and all plumbing and valves are up to date.

With the addition of the hoop building last summer, we now have over 30,000 tons of dry storage in Audubon. The benefit of this investment translates into less down time for you. While many retailers ran out of product this spring, we never did. We have been receiving product daily and are nearly full. We will have a good supply of product for fall. Periodic maintenance on all drags, legs and blending equipment has been completed.

We have updated our dry fertilizing tending equipment and have two new Timpte trailers for fall. All lime spreading equipment has been serviced and is ready to go.

We will once again offer custom ammonia application, dual placement application, dry banded application, dry spreading & lime spreading.

Plan Ahead

The busy harvest season will soon be upon us and fertilizer application shortly after that. Please take the time now to start planning for your fall fertility needs. Thanks for all your past fertilizer business and we look forward to working with you again this fall.